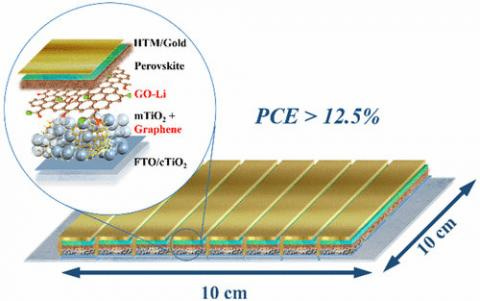

Perovskite/silicon tandem solar cells promise to push the market-leading crystalline silicon technology beyond its theoretical limit while maintaining low fabrication costs. The possibility to fabricate the perovskite top cell by low-cost solution processing may decrease the levelized cost of energy of photovoltaics toward the grid-parity milestone. However, the solution processing of perovskite solar cells directly onto the textured front surface of high-efficiency amorphous/crystalline silicon heterojunction cells is the main bottleneck. Prospectively, performance improvements and upscaling of perovskite solar cells, as well as the background knowledge on electronic component bonding method, make last results relevant to drive economically feasible perovskite/silicon tandem PVs.

Graphene-enabled perovskite panels are created by a chemical deposition that is applied to a substrate. This straightforward application process and the promise of the technology make for an attractive prospective, especially in areas that desire versatile and lightweight solar power solutions. Even though perovskite cells have demonstrated exceptional potential, with efficiency increases going from 12% to more than 23% in four years, their efficiency diminishes significantly as panel size increases.

Stability is also an issue with graphene-enabled perovskite panels. The longest lifespan documented for a perovskite panel is around 12 months, which is much shorter than the 25-year lifespan of conventional solar technologies.

The emerging graphene solutions being used in photovoltaics are expected to unlock more effective and dependable solar panels. This will only add to the usage and propagation of affordable, renewable, and clean energy.

For both solar panel systems and wind turbines, the past few years have seen a remarkable drop in the levelized cost of energy (LCOE); a term used to describe the average cost to create electricity over the lifetime of a facility.

According to data from the International Renewable Energy Agency, the LCOE for solar decreased by 82% between 2010 and 2019. For onshore wind, it dropped by 39%, and for offshore by 29%. These kinds of reductions make renewable energies a lot more competitive or even less expensive than the cheapest fossil fuels. Continual research and development will enable even more efficient solutions, which allows us to meet even more progressive goals for climate change mitigation.

When the tradeoff between conversion efficiency and cost comes into play, the advantage could go to solar cells that are amenable to high-volume, low cost manufacturing techniques. The new research is a collaborative effort between the EU’s Graphene Flagship initiative at the University of Rome Tor Vergata, the Italian Institute of Technology, and an IIT spin-off, the graphene specialist BeDimensional and the Spanish clean tech company ENEA.

You can get all the details in the paper, “Mechanically Stacked, Two-Terminal Graphene-Based Perovskite/Silicon Tandem Solar Cell with Efficiency over 26%,” newly published in the latest issue of the journal Joule.

For those of you on the go, the team started with the premise that perovskite/silicon tandem solar cells could be the next big thing, due to a killer combo of relatively low manufacturing costs plus a decent chance at exceeding the solar conversion efficiency limits of silicon alone.

The bottleneck is — or was — on the manufacturing side, until the team figured out a workaround.

“The solution processing of perovskite solar cells directly onto the textured front surface of high-efficiency amorphous/crystalline silicon heterojunction cells is the main bottleneck,” the researchers explain. “Our simple two-terminal mechanical stacking of the sub-cells helps achieve highly performant PV devices.”

Basically, the new approach is to configure each part of the solar cell before hooking them all up together with an assist from graphene-based ink.

According to the researchers, the new technique can be applied to the existing crop of perovskite solar cells, using standard solution-based manufacturing methods.

Emmanuel Kymakis, Graphene Flagship Energy Generation Work Package Leader, provides the technical explainer (GRMs refers to graphene and other inks made with 2-D materials).

“This pioneering work demonstrates that the integration of GRMs inks with on-demand morphology and tuneable optoelectronic properties in a tandem structure, can lead to high-throughput industrial manufacturing,” he said. “Graphene and related materials improve the performance, stability and scalability of these devices.”

Video Courtesy: Perovskite Solar Cells Surpass 20% Efficiency. EPFL researchers are pushing the limits of perovskite solar cell performance by exploring the best way to grow these crystals.

Don't hesitate to subscribe if you haven't already done so.

Regards and take care.

Born in 2012, Scixel is a project devoted to the improvement of the scientific comunication through the creation of graphical products: pictures, animations, graphs, posters, etc. Scixel consists of scientists with a deep knowledge in digital graphics but also with a long experience in giving talks, preparing posters and papers and other daily situations of scientific work.

We have focused our work into universities and research institutes all over the world: TuDelft (The Netherlands), NIMS (Japan), Basel University (Switzerland), Universidad Autónoma de Madrid, CNB or ICFO (Spain), to name a few.

Web: https://scixel.es/

If you are a company or an individual who would like to place your advertising in my newsletter you can contact me (email) and let me know your request of type of ad and number of newsletters you would like to place it. I will send you a budget as soon as possible.