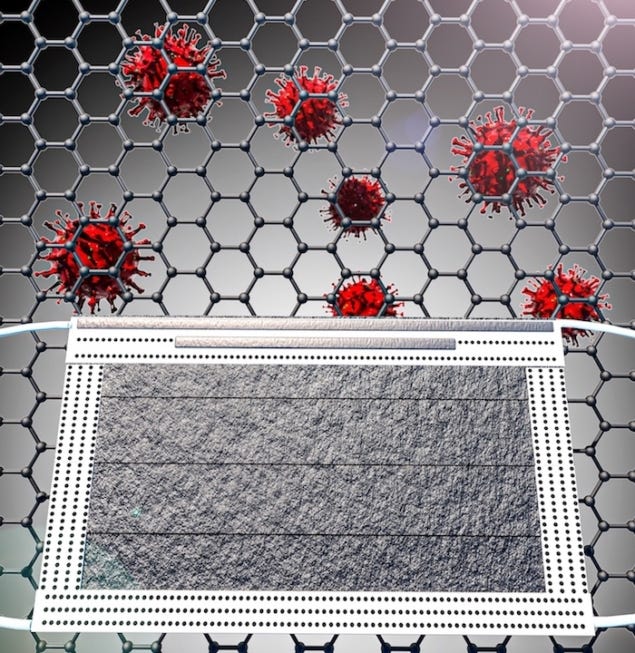

The graphene-coated mask. (Courtesy: G Li )

It seems like yesterday but it has been 12 months since the first news of a new coronavirus that had started infecting humans hit the international media.

The first few weeks I remember were chaotic. We had very little information about the coronavirus and could only confine ourselves to being confined to the house for as long as possible and follow the recommendations of face masks, hydroalcoholic hand gel and social distance when shopping for essential items at the supermarket or pharmacy.

At the same time as we were trying to protect ourselves personally against this coronavirus, a very large number of researchers were working to obtain a cure in the shortest possible time, a vaccine that would immunise us all. People wondered how this could be possible in such a short time. It is as easy as thinking about the advances that science has made today. We can´t imagine those early researchers at the beginning of the 20th century when the bad called "Spanish fever" was entering Europe via the ships that docked in northern Italy. With the means available to them at the time, they must have worked near miracles to achieve results.

Nowadays we have very advanced technology, as well as researchers with great potential that allow us to obtain results in less time.

While the biologists had already started the race against the clock to obtain the different vaccines, there was another group of researchers (physicists, chemists, biologists, engineers) who were beginning to take part in this race to find a solution to fight the coronavirus that did not go the way of the vaccine. I am referring to the manufacture of highly sensitive devices for the detection of the coronavirus as well as new materials that could fight against the infection.

Among the devices that could help us detect the coronavirus in asymptomatic/symptomatic people, I would like to highlight research into biosensors. There are currently many groups in the world working in this field and we recently organised the second edition of the conference "Biosensors for Pandemics" where the latest advances were presented. If anyone is curious, the website is - www.confstreaming.com/Biosensors2021/index.php and in it you can find the different papers presented as well as the complete book of Abstracts available for download

One of the most interesting talks was presented by Vincent Bouchiat (Grapheal, France). This work shows the use of graphene in biosensors.

Bio: Vincent Bouchiat is the CEO of Grapheal, a company spin-off from Neel Institute focusing on bioelectronic and healthcare applications of graphene. He is on leave from the French National Research Center (CNRS) at Grenoble, where he has a permanent position since 1997. He received an engineer degree from ESPCI in 1993 and a Master Degree from the University of Paris, Pierre & Marie Curie the same year. He has completed his Ph.D. on quantum devices at CEA-Saclay in 1997 under supervision of Michel Devoret and Daniel Estève. He got the Visiting Miller Professorship Award from University of California, Berkeley in 2007, and the Lee Hsun Research Award from the Chinese Academy of Sciences (2017). He co-authored more than 100 publications with over 4000 citations and hold 9 international patents.

On Grapheal's website (www.grapheal.fr), Vicent presents his company's solution using a graphene biosensor.

Grapheal is developing a diagnostic test based on saliva sampling to screen Covid-19 infection rapidly in response to the current sanitary crisis. This all-electronic test is an antigen immunoassay: it detects the virus's presence and not the immune response commonly found in current-generation rapid tests. It allows the result to be electronically captured at the heart of the device, which speeds up the diagnosis and enables the result's secure digital transfer.

When sensitized with appropriate antibodies, which target the proteins at the surface of the SARS-CoV-2 virus, graphene sees its electrical conductance affected by the virus's presence. It can detect the virus in body fluids, thus providing highly efficient diagnostic tests.

(Courtesy: Grapheal)

Grapheal is designing an innovative graphene-based SARS-CoV-2 sensor, and we used SAMSON to help them communicate about their project by creating an animation describing the sensor structure and mechanism.

The latest news about Grapheal and its research hit the media this week:

Grapheal Raises EUR1.9 Million to Advance Development of Embedded Biosensing Technology and Application in Digital COVID Testing and Wound Monitoring

Grapheal, a developer of graphene-based embedded biosensors for on-site diagnostics and remote patient monitoring, announced today that it has raised a total of EUR1.9 million in equity and non-dilutive sources, including seed financing from Novalis Biotech’s Acceleration Fund, several innovation grants, and Bpifrance convertible notes and loans.

The funds will be used to advance the industrialization of Grapheal’s flexible graphene-based biosensor technology. This sensing technology combines novel electronic nanomaterials, embedded wireless electronics, software data analysis, and medical cloud IoT technologies. The first two applications of the technology will be a new generation digital COVID-19 test (TestNPass) for rapid screening in high-traffic areas, such as airports, and a wound care digital assistant (WoundLAB) to improve the monitoring of hard-to-heal wounds. The funds will also be used to validate the two devices in the field and complete clinical studies, respectively.

“Grapheal merges digital bioelectronic sensing technologies with connectivity into embedded systems for on-site diagnostics and remote patient monitoring, so is a perfect fit to the Novalis portfolio” said Wim Van Criekinge, co-founder of Novalis Biotech, who has also been appointed to the Grapheal Board of Directors. “There is enormous potential for applications of their digital technology in the medical field, but the rapid COVID-19 saliva test could be the game-changing test the world needs to safely return to normal, particularly at airports, concert halls, and stadiums. Their technology is delivering a tamper-proof sanitary pass that is confidential and compliant with stringent data privacy regulations, such as European GDPR. This is definitely a critical asset for their differentiation with competing products.”

TestNPass is Grapheal’s diagnostic test based on saliva sampling that can be used to rapidly screen for the COVID-19 infection. Within 5 minutes, the digital test detects the presence of the virus without the requirement of dedicated reading equipment other than a smartphone or a standard NFC-connected device. When the SARS-CoV-2 virus binds to antibodies contained in TestNPass, a specific electrical signal is detected. This signal can be captured electronically on the device, which speeds up the diagnosis and allows the result's secure digital transfer.

WoundLAB is a flexible and transparent graphene-based biosensor patch that continuously records and stores wound biochemical parameters. A smartphone app is then used to communicate this data to a telemedicine cloud for data aggregation and further analysis. This allows caregivers to monitor wound healing in their patients remotely, with prompt alerts if any infections or medical complications arise.

“We are very thankful to everyone that participated in our funding, from the seed capital provided by Novalis Biotech, each grant approval, and the Grenoble and La French Tech teams at Bpifrance for their continuous support,” said Dr. Vincent Bouchiat, CEO of Grapheal. “The medical applications of graphene are only just beginning to be explored, and we are leading those endeavors. With this funding in place, we believe our first product could be on the market before the end of 2021.”

Another talk at the congress was given by Gei Gao (California Institute of Technology, USA) entitled "SARS-CoV-2 RapidPlex: A Graphene-Based Multiplexed Telemedicine Platform for COVID-19 Diagnosis".

Bio: Wei Gao is an Assistant Professor of Medical Engineering in Division of Engineering and Applied Science at the California Institute of Technology. He received his Ph.D. in Chemical Engineering at University of California, San Diego and was a postdoctoral fellow in the Department of Electrical Engineering and Computer Sciences at the University of California, Berkeley. He is a recipient of IEEE EMBS Early Career Achievement Award, IEEE Sensor Council Technical Achievement Award, MIT Technology Review 35 Innovators Under 35, and ACS Young Investigator Award. He is a Highly Cited Researcher (Web of Science), a World Economic Forum Young Scientist, and a member of Global Young Academy. His research interests include wearable biosensors, digital medicine, micro/nanorobotics, bioelectronics, flexible electronics, and nanomedicine.

Asbtract: The COVID-19 pandemic is an ongoing global challenge for public health systems. The need forwidespread testing to control the spread of COVID-19 has faced challenges due to testing backlogs, limited access to required equipment, and inaccurate assay results.[1] To address this, we demonstrate an ultrasensitive telemedicine platform, the SARS-CoV-2 RapidPlex, based on targetspecific immunoassays for rapid and remote assessment of COVID-19 biomarkers (i.e., nucleocapsid protein, anti-spike protein IgG and IgM, and C-reactive protein).[2] Multiplex sensing of these targets provides information on three key aspects of COVID-19 disease: viral infection, immune response, and disease severity. The platform uses capture antigens and antibodies immobilized on mass-producible, low-cost, laser-engraved graphene electrodes.[3,4] We successfully evaluated the platform's applicability using COVID-19-positive and COVID-19-negative serum and saliva samples. The SARS-CoV-2 RapidPlex has the potential to quickly and effectively triage patients and track infection progression, allowing for the clear identification of individuals who are infectious, vulnerable, and/or immune. Based on this pilot study, our multiplexed immunosensor platform may allow for high-frequency at-home testing for COVID-19 telemedicine diagnosis and monitoring.

Another example of the use of graphene to combat the coronavirus is planarTech's masks.

Another example of how nanotechnology can help us in the fight against the coronavirus are the masks manufactured by the company Bioinica in collaboration with the CSIC. Their website is: https://bioinicia.com

According to their own website: PROVEIL® is a new filtration media developed by the Spanish National Research Council (CSIC) and Bioinicia, leaders in the field of nanofibres for medical and healthcare applications.

When the pandemic broke out, healthcare workers suffered from a lack of supply of critical protective equipment.

To respond to this demand, CSIC and Bioinicia dedicated its resources to the development of a respiratory mask filter that would protect key workers from the virus, and shifted its pharmaceutical manufacturing facility to produce PROVEIL® for supply to mask manufacturers across Europe.

Most respirators in use today are based on polypropylene melt-blown non-woven fibres, sandwiched between spunbonded non-woven layers of polypropylene. Their effectiveness in filtering out small particles in the air is based on electrostatic surface charges, which attract and capture these particles from the air as it passes through the filter. This electrostatic filtering effect only works when the mask is dry and disappears quickly during use, as the moisture produced by the breath removes the electrostatic charge. It is for this reason that spunbond / meltblown / spunbond (SMS) filters are not suitable for continuous use and should be discarded and replaced frequently.

PROVEIL® is different. An extremely thin layer of nanofibres, with diameters more than ten times smaller than conventional fibres, provides highly effective mechanical filtration for small airborne particles with no reduction in efficiency over time. The larger surface area and smaller pore size of the PROVEIL® filter maximises the likelihood of particles being stopped by the fibres without relying on electrostatic attraction. This means that PROVEIL® filters continue to provide effective protection over time.

In our need to respond to the lack of protection resulting from the pandemic, CSIC and Bioinicia have developed a range of masks with the PROVEIL® nanofibre filter.

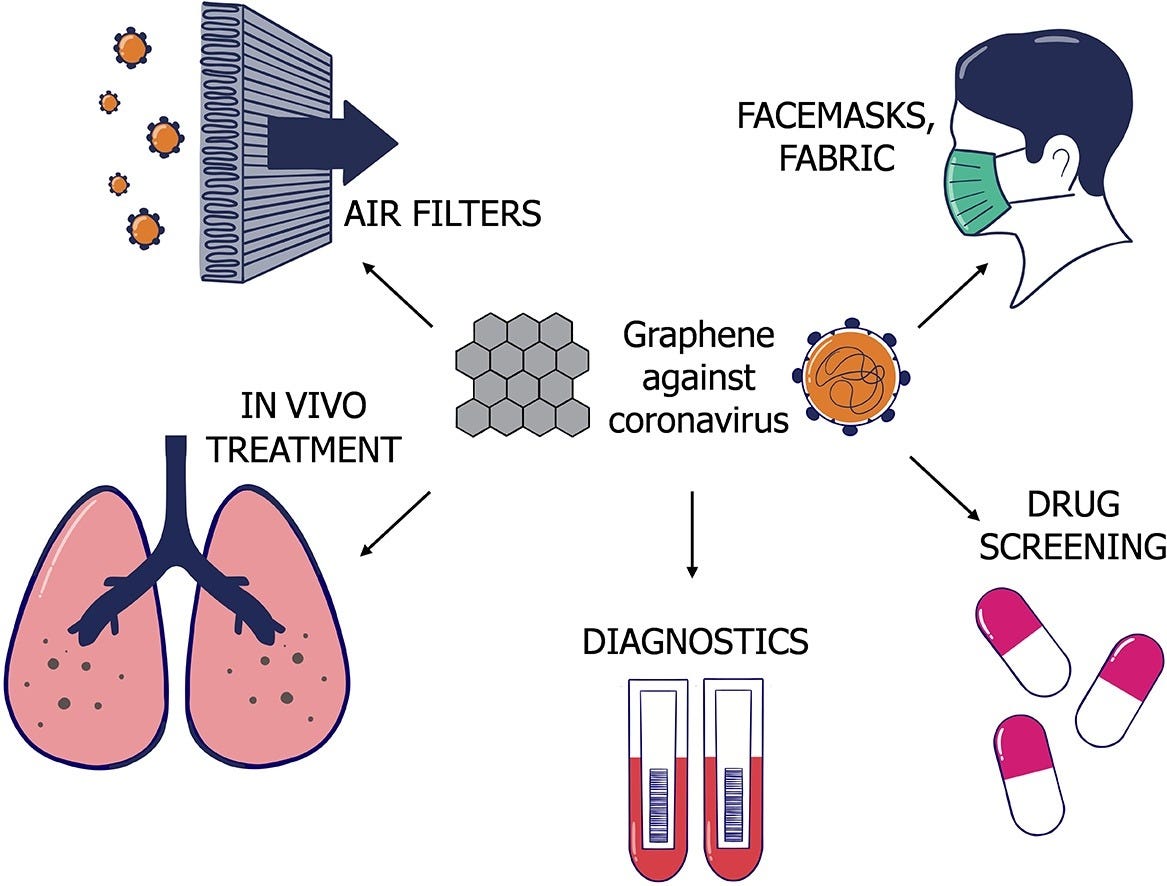

More than a few companies have launched graphene-enhanced textiles, inks and coatings, incorporated into personal protective gear (face masks, gloves etc.), and applications like air filters and room cleansers have been developed.

This has been seen both in companies that have already started in this route before the pandemic, and from ones that have done a bit of "tuning" of their portfolio. There has been some repurposing of smart materials to design effective systems for combating COVID-19. Functionalized graphene demonstrates a good viral capture capacity that, combined with heat or light-mediated treatments, could be used as a disinfectant. So, a strong emphasis on environmental sensors and filters is clearly seen. In addition, graphene sensors can be implemented on standard textiles and drug efficacy screening, also contributing to various PPE applications. Coatings for protection of surfaces are being developed, as well as disinfectant solutions and detergents containing graphene and related materials to clean surfaces.

Some examples of graphene-enhanced applications to battle the Coronavirus are:

1. UK-based planarTECH and Thailand-based IDEATI have started marketing and distribution of its 2AM-branded graphene-enhanced antibacterial face masks.

2. Haydale Graphene Industries announced that its partner IRPC has completed the development project with Haydale and started production of its new washable functionalized graphene-enhanced fabric mask.

3. Versarien announced the launch of its first graphene-enhanced protective face mask, which utilizes Polygrene, Versarien’s graphene-enhanced polymer.

4. A firm called Flextrapower (formerly Bonbouton) was created to leverage research originally created in Stevens labs for biomedical applications. Flextrapower has been developing several graphene-based applications, including the most recent COVID-focused effort, a graphene mask.

5. A consortium of Spanish scientists and companies, in which the University of Granada (UGR) is participating, has been developing new efficient prophylactic facemasks to combat the Coronavirus responsible for COVID-19. These masks will be made of non-woven textiles specially modified with graphene and derivative materials.

6. A research team from City University of Hong Kong (CityU) announced the production of graphene masks with a reported anti-bacterial efficiency of 80%, which can be enhanced to almost 100% with exposure to sunlight for around 10 minutes.

7. Researchers at the Fraunhofer Institute for Reliability and Microintegration IZM have joined forces with partners in industry and healthcare to develop a graphene oxide based sensor platform to detect acute infections such as sepsis or the antibodies against the coronavirus within minutes.

8. Caltech researchers have developed a new type of multiplexed test with a low-cost sensor that may enable the at-home diagnosis of a COVID infection through rapid analysis of small volumes of saliva or blood, without the involvement of a medical professional, in under 10 minutes.

9. Grolltex has teamed up with Sanford Burnham Prebys Medical Discovery Institute to develop a graphene-based virus testing platform to help combat COVID-19. The project involves using handheld reader units and disposable plastic testing chips designed for U.S. points of entry including hospitals and “point of care” locations.

10. G6 Materials (formerly Graphene 3D Lab) is optimizing the business model to accommodate the new reality of Covid-19. As part of this, G6 has developed a graphene-based air purification tech that could help fight the virus.

11. University of Illinois researchers have used graphene to develop a rapid, ultrasensitive test using a paper-based electrochemical sensor that can detect the presence of the virus in less than five minutes.

In the next issue of this newsletter I will have the possibility to offer you the first of a series of interviews with young researchers. Don't hesitate to subscribe if you haven't already done so.

Best regards and take care